AddTime:2023-03-12 Hits:834

Electronic assembly glue without pressure preservation _ENIENT reactive hot melt glue to solve your bonding problem

I Silicone adhesives are more environmentally friendly, but the bonding strength is general, and the curing speed is generally often used to assemble the parts that are easy to remove. One of these two types of glue is volatile curing type, one is room temperature vulcanization type, which takes a certain amount of time to reach the strength of preliminary curing. After bonding, pressure keeping operation is needed to prevent the relative displacement and deformation of the adhesive surface, otherwise it will seriously affect the bonding effect and shorten the service life of the assembly.

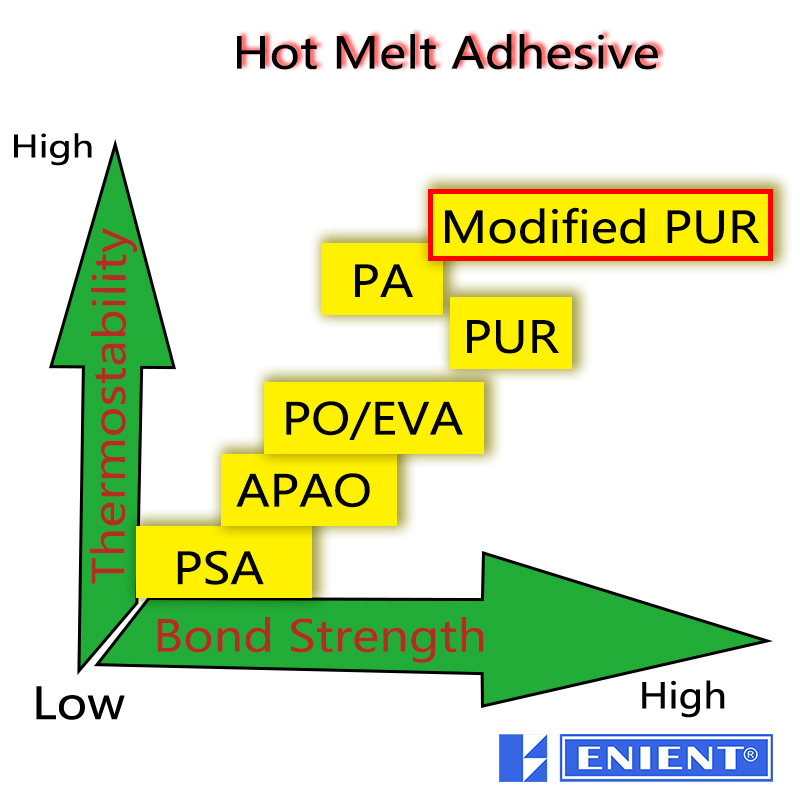

With the pursuit of high speed and high efficiency in the production of modern electronic products, the time of pressure retaining operation is required to be greatly shortened or directly cancelled, etc. At this time, the curing speed of adhesives is required to be fast, the strength is high, and the bonding effect is better. Therefore, in order to meet the higher precision electronic products assembly, in recent years, a new type of adhesive-reactive PUR hot melt, it can by heating rapid curing, high strength, and no solvent, will not pollute the environment, for electronic products assembly more environmental protection, and without pressure process, a few minutes can have higher strength, make the product will not appear deformation and cracking, can be the next process. This greatly optimizes the production process, saves the production time, and improves the production efficiency.

ENIENT Reaction hot melt adhesive is designed for modern electronic production assembly industry and development, the heating curing, it has super bonding performance, has good moisture resistance, durability, low temperature bonding, non-toxic harmless, can be applied to all kinds of electronic assembly process, meet the production requirements of high efficiency, is an ideal adhesive in the electronic assembly industry. It is suitable for a variety of common electronic materials, such as metal, plastic, glass, etc., more importantly, its bonding strength is high, a wide range of temperature resistance, can meet the high requirements of customers. And it also has a lot of uses, not only can do structural bonding, but also has a very good sealing performance, can be used as a fixed seal. It can also be used for insulation and fixation, especially where there is a wet environment, so that it can extend the service life of the cable and ensure the stability of the work.

And compared with dissolved adhesives, it also has a wider range of temperature use, from-50 degrees Celsius to high temperature series of 150 degrees Celsius, ENIENT reactive adhesives can easily deal with.

ENIENT ® products are the key to a clean and safe working environment across a wide range of industries. Our innovative and reliable super-safe rust remover delivers uncompromising performance, making rust removal a very simple job. Our rust remover can be easily applied to scenes that need rust removal. It can replace refrigerant and rust removal oil, making rust removal easier and eliminating additional rust removal processes.

We ensure that you have easy access to technical information and resources to identify the right product for your specific application, sector and industry. We offer comprehensive support to let you know more about our innovative rust removal solutions and how they can help you.

For more information about the product, CONTACT ENIENT CHEM and consult to one of our technical advisors. Browse our product range and download technical datasheets to learn more about the specific performance, compatibility, and application of each descaling scenario.

- Rust remover technology AC group

Scanning WeChat QR Code add service

Scanning WeChat QR Code add service - Metal rust removal case sharing group

Scanning WeChat QR Code add service

Scanning WeChat QR Code add service - Rust remover operates AC group

Scanning WeChat QR Code add service

Scanning WeChat QR Code add service - Rust remover case sharing group

Scanning WeChat QR Code add service

Scanning WeChat QR Code add service - Ac group for equipment rust removal

Scanning WeChat QR Code add service

Scanning WeChat QR Code add service

- Efficient application of neutral rust remover for Mercedes Benz models

- ENIENT develops a new type of fast reaction neutral rust remover

- ENIENT rust remover products does not damage the metal

- Principle of non-corrosive rust remover not corroding metal and plastic

- Difference between non-corrosive and neutral rust remover

- Pre-sale Services

- Technical Support

- 17727177192

-

Scan to add Wechat

Scan to add Wechat - Up to top